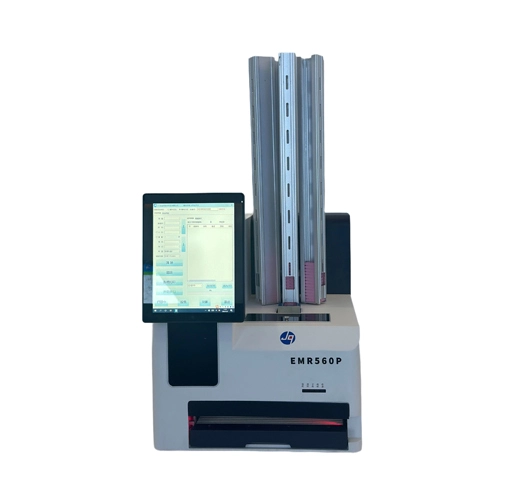

Application of Laser Casssette Printers in Pathological Technology Processes

In recent years, with the gradual increase in the number of clinical pathology specimens, the usage of disposable plastic cassettes has also grown. The traditional method of manually writing on cassettes can no longer meet the evolving needs of pathology departments. Consequently, cassette marking machines have emerged and have gradually been adopted by various hospitals and laboratories. Laser cassette printers have significantly improved the writing efficiency, and the pathology numbers printed on the cassettes are concise and clear.

Innovative Application of Laser Cassette Printers

The laser cassette printer generates a high-energy continuous laser beam through the laser generator, which focuses on the surface of the embedding cassette. The surface material instantly melts or even vaporizes due to the laser, and the galvo mirrors control the laser's path on the cassette surface to form laser-engraved marks. This achieves the required digits and patterns using a non-contact high-energy focused laser technology, which can mark on any irregular surface without deformation or internal stress, making it suitable for marking almost all materials. The diameter of the focused laser beam is only 0.01 mm, allowing the printed digits and patterns to be very detailed, achieving a resolution of 100 dots/mm. Moreover, being non-contact printing, the laser can achieve consistent marking effects within a focal distance of ±1 mm, so the requirements for the embedding cassette surface are not stringent. Even if the surface has blemishes, it can still print clear digits and patterns. This laser casssette printer technology is a domestically developed product in China, with no equivalent technology products available internationally.

Efficiency and Stability of Laser Cassette Printers

Currently, the laser cassette printer is the most advanced equipment in the field of embedding cassette printing technology, both domestically and internationally. The printing speed can reach 12 units/min. Assuming a daily printing of 2000 embedding cassettes, the printing time reduces from nearly 700 minutes to less than 200 minutes. The pause time caused by cartridge jams decreases by 75% to 83%, significantly enhancing work efficiency in the pre-printing phase of cassettes.

Laser Cassette Printers improve the efficiency of pathology specimen processing

The laser-printed fonts form an integral part of the embedding cassette, preventing loss or incomplete display of QR code data and numbers due to blade scraping the surface of wax blocks. This avoids failures in scanning and identifying during the slicing process, ensuring effective and timely extraction of wax block information. The scanning recognition rate for laser-marked embedding cassettes is increased to 100%, and the individual cassette scanning speed is fast, greatly improving the scanning speed of slices and subsequently enhancing the efficiency of the slicing process.

The pathology cassette printer can achieve high-throughput printing, with a maximum capacity of 600 embedding cassettes at one time. Additionally, it can use cassettes of different colors, allowing for intuitive differentiation and classification of tissue types, employing different dehydration, embedding, slicing, and staining procedures as required. This provides a solid foundation for the classification and graded management of pathology specimens.

Laser cassette printers represent a brand-new technology, completely transforming the traditional inkjet and carbon ribbon marking machine models. Without the need for cartridges or ribbons, non-contact printing ensures high reliability, low printing costs, no noise, and no chemical pollution. It enables batch loading and batch printing of embedding cassettes with high speed and clarity. This technology should be widely applied in the digital information scanning and recording processes throughout the pathology technology workflow.