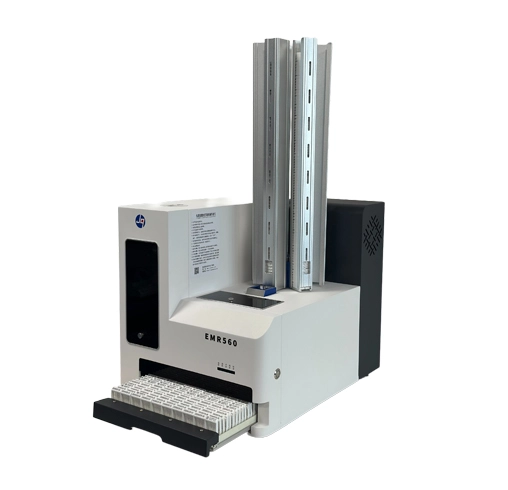

The Structure of a Histology Slide Label Printer

In modern pathology laboratories, histology slide label printers have become an indispensable and highly instrument. They significantly enhance the efficiency and quality of pathological diagnosis, sample management, and research work by accurately and quickly printing label information on slides.

Print Head

Technology Choice

The print head of a histology slide label printer is a critical component, typically utilizing either inkjet printing or laser printing technology. An inkjet print head can precisely spray ink onto the slide surface, forming clear text and graphics. Laser print heads utilize laser beams to mark the slide, offering advantages such as no need for consumables and fast printing speeds.

Precision Assurance

Regardless of the technology used, the print head can achieve high-resolution printing effects, ensuring that the label information on the slide is clear and recognizable. This is crucial for pathologists to accurately identify sample information under a microscope, contributing to improved diagnostic accuracy.

Slide Feeding System

Slide Cassette Design

Histology slide label printers are equipped with dedicated slide cassettes for neatly storing slides to be printed. This design not only facilitates the management and retrieval of slides but also lays the foundation for automated printing.

Feeding Channel Function

After being extracted from the cassette, the slides are smoothly and accurately transmitted to the area beneath the print head through the feeding channel. The design of the feeding channel is crucial; it ensures the stability and positioning accuracy of the slides during the printing process, preventing printing errors caused by slide misalignment.

Control System

User-Friendly Interface

The operation interface of a histology slide label printer is typically a user-friendly touch screen or PC software. Through these interfaces, users can easily input the information to be printed, such as patient names, sample numbers, pathological diagnoses, and set printing formats, positions, and other parameters.

Data Transmission Interface

To achieve seamless integration with laboratory information systems, histology slide label printers are equipped with data transmission interfaces, such as USB or network interfaces. These interfaces allow the printer to receive data information from LIS systems, enabling automated printing and reducing manual input errors and workload.

Ink System (Inkjet Printers)

Ink Cartridge Features

Inkjet histology slide label printers require specialized ink cartridges to provide ink. The ink in these cartridges has excellent chemical corrosion resistance and physical wear resistance, ensuring that the printed label information remains clear throughout histological processing and long-term storage.

Ink Circulation System

Some inkjet printers are also equipped with an ink circulation system, which maintains the flow and even distribution of ink, effectively preventing the drying or clogging of nozzles and ensuring the stability and continuity of the printing process.

Unloading System

Unload Station Capacity

After printing, slides are transferred to the unload station via the unloading system. The design of the unload station can accommodate a certain number of printed slides, making it convenient for users to collect and organize them, thereby improving work efficiency.

Collecting Tray Stability

In the unloading station, the collecting tray is used to store printed slides. Its design ensures that the slides can be placed neatly and stably, preventing damage or confusion during collection and ensuring the integrity and traceability of the samples.